Taps (TK / HM; HSS-; HSS-E; HSS-Co; HSS-PM)

hand taps, conventional taps, machine taps for through holes, machine taps for blind holes, synchronous taps, forming taps, thread milling cutters

Calibers

Thread Go/No Go plug gauge – the mandrel is designed to check the internal threads

“Go” threaded mandrel – serves for checking both the middle diameter of the thread and keeping the lower limit dimension of the large diameter.

No Go threaded mandrel – checks whether the actual mean diameter of the thread does not exceed the specified largest dimension. It can be easily screwed into the thread under test for a maximum of two turns!

Limit thread gauge – ring is used for checking external threads.

Gothreaded ring – designed for checking the middle diameter of the thread. It must be possible to screw in by hand over the entire length of the thread.

No Go threaded ring – determines whether the actual dimension of the thread’s center diameter is less than its smallest prescribed thread size. It can be easily screwed up to a maximum of two turns!

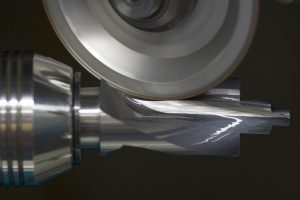

Sharpening and coating tools

We offer our customers the possibility of sharpening and coating tools. Sharpening is carried out on the most modern machines. The type of coating is then selected, depending on the particular application of the tool for the material. Several types of coatings are available, e.g.

TiN , TiCN, TiCC, Alcrona, AlTiN, AlTiN HARD, AlTiSiN, CrN, MDT, MDT+, or. Low temperature cycles below 200°C.