Monolithic tools

(TK / HM; HSS-; HSS-E; HSS-Co; HSS-PM)

core drills, countersinks, sheet peeling drills, micro drills, mini drills, NC drills, countersinks, flat countersinks, short drill sets, spiral drills, center drills, countersink drills, flat center drills, step drills for through and through holes , step drills 90 ° (for tapped holes), HPC-4 chamfer drills, deep hole drills (16xD, 20xD, 25xD, 30xD, 40xD, 50xD), single flute gundrills with brazed carbide head, parallel hole drills, multi-facet drills, drills for sheet metal, drills with 4 cooling channels

Tools with indexable inserts

NC drills, CrownLoc (drill bits, drill bodies), indexable insert holders (VBD), HiPer-Drill, lance drills, KUBCentron, KUBCentron Powerline, KUBPentron, KUBQuatron, KUBTrigon, material HSS, HSSCo, HSSCo 8%, K10, K20, K35, P40, tools for deep hole drilling up to 30xD, PowerDrill, universal drills with solid inserts, Base body MT shank

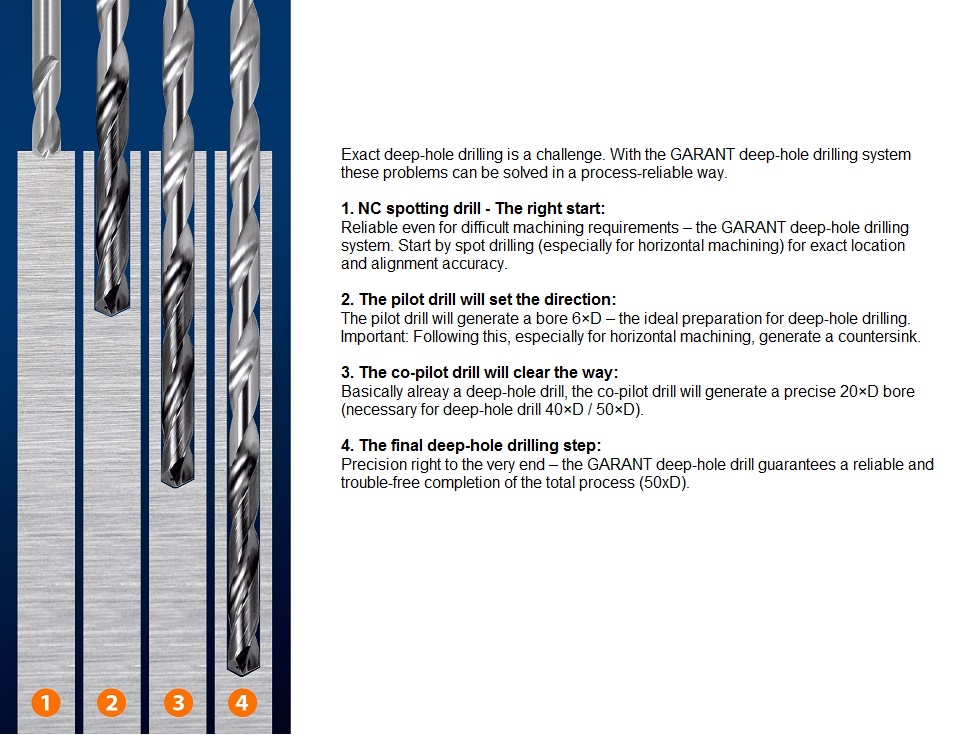

Deep drilling

(16xD, 20xD, 25xD, 30xD, 40xD 50xD)

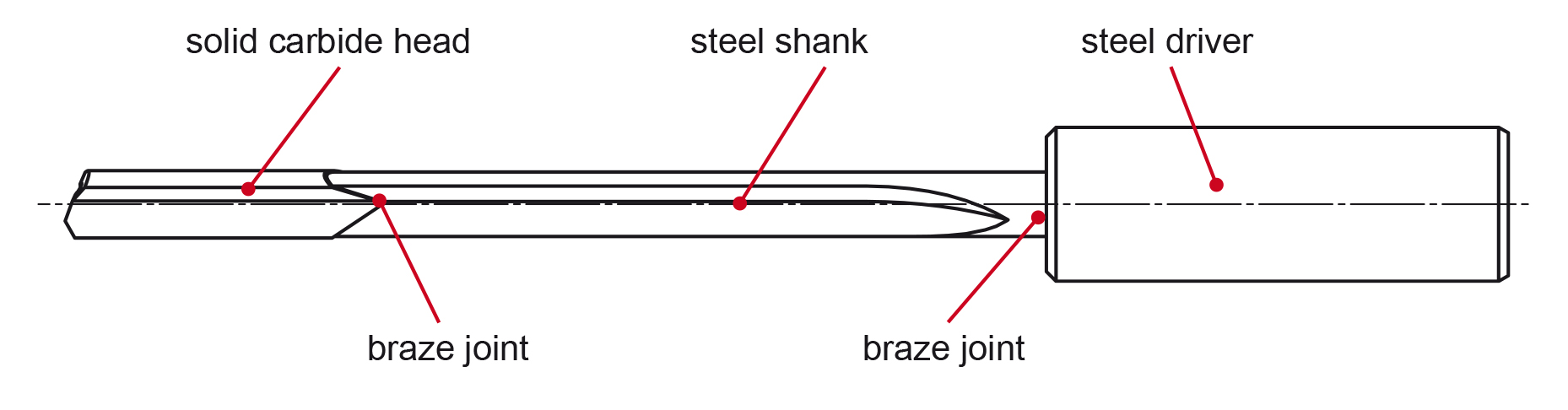

Single flute gundrills with brazed carbide head – Technology of gun drilling:

Typ 100

Single flute drill with a brazed carbide head Type 100 are connected by a braze joint and consist of the following three components:

-solid carbide head

-shank of tempered steel

-driver of steel

Diameter range:: from 1,85mm to 54,00mm

Length range: until 3m

What is gun drilling?:

Deep drilling is a technology that allows drilling holes from 1mm to 50mm in diameter. The drilling depth depends on the diameter of the hole (drill) and the type of material to be drilled. As long as the principles and technology of deep hole drilling are adhered to, even at a depth of, for example, 1,000 mm, the hole diameter can be kept within the H8 tolerance and the axial inaccuracy of the hole opening is, even at this depth, within tenths of mm. The maximum depth of gun drilling, as such, lies at the 6,000mm boundary. The drilling itself is performed by a cannon drill. It is a special single flute gundrills with brazed carbide head and up. shank with cavity for coolant supply (oil mist).

General procedure: The drill is, with the speed switched off, inserted into the pre-drilled hole, to a depth of approx 35-40mm. Speed and feed are started, and without interrupting the cut, is drilled on required depth. When the desired drilling depth is reached, the drill bit is switched off, and the drill bit is extended (usually at rapid traverse).

Advantages of gun drilling:

The main advantage of gun drilling is the complete simplicity and versatility of this technology. Gun drilling, using the technology we supply, can be deployed on any commercially available production machines with sufficient feed range such as horizontal boring machines, jig boring machines, CNC milling machines, column and radial drilling machines, lathes, etc.). Thanks to the fact that the drilling is performed by means of machine feed and continuous cutting, it saves not only the machine time and the machine, but also the machine operator, in comparison with conventional HSS drilling. The real saving of machine time compared to drilling with HSS extension drills is 80-90% of the machine time. A very important advantage of gun drilling is the process reliability. For example, if the drill is damaged or twisted during deep drilling, it becomes 90% certainty at the brazed joint of the carbide tip and the drill bit body. But how to deal with it? Remedy is very simple. Using a long steel rod, crush the rest of the blade left in the drill hole, blow it out with compressed air, fit a new cannon drill and continue drilling. It should be noted that the price of cannabis drill bits above 300mm is generally lower than the HSS drill bits. The prices of cannabis drills are different when purchasing 1, 2 and 3 pieces. For the first investments we always recommend buying min. 2 pieces of cannon drills, when it is calculated with subsequent refocusing and possible damage to the drill.

Disadvantages of gun drilling:

NDisadvantages of gun drill is work produktivity. This disadvanatages is evident when we use drills with smaller depth – 20D. Anyway, gun drilling technology haven´t competition!

What do I need to drill deep holes with gun drilling technology?

1. Single flute gundrills with solid carbide drill head, with right average and length, typ 100

2. Clamps for the supply of coolant or oil mist, or clamps for the supply of compressed air or oil mist

3. Micro Lubrication VM1N

Application range:

Gundrilling on conventional machines without high pressure.

Properties:

-easy handling

-reduced investment costs

-less space required

-flexible use on various machines

-no interruption of production flow

Requirements:

– Internal compressed air system needed to implement gun drilling technology

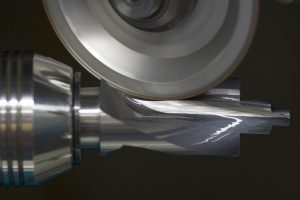

Sharpening and coating tools

We offer our customers the possibility of sharpening and coating tools. Sharpening is carried out on the most modern machines. The type of coating is then selected, depending on the particular application of the tool for the material. Several types of coatings are available, e.g.

TiN , TiCN, TiCC, Alcrona, AlTiN, AlTiN HARD, AlTiSiN, CrN, MDT, MDT+, or. Low temperature cycles below 200°C.